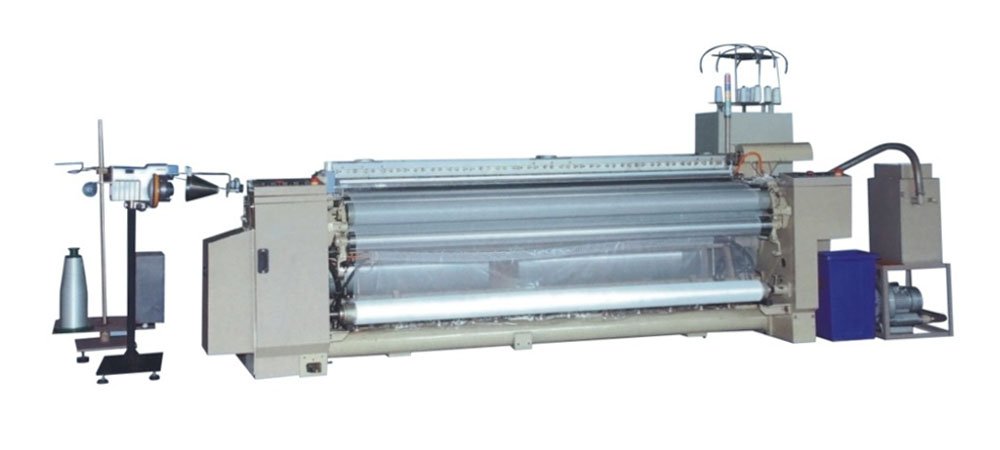

Fiberglass jet loom is a jet loom specially designed for weaving fiberglass fabrics. Suitable for weaving fabrics such as lacquered fabric, laminated fabric, and copper-clad laminates made from fiberglass as raw materials. This loom is suitable for weaving light, medium, and heavy fabrics. It can be used for lightweight fiberglass fabrics weighing 50g/m or less, and can also be used for weaving heavy-duty fiberglass fabrics weighing 300g/m. It has the characteristics of low weft wear, high output, good quality, smooth operation, and low noise, and has a good cost-effectiveness advantage for users. The loom uses a crank opening, or a cam opening, with 4-8 sheets of heald, using a single nozzle. The main and auxiliary nozzles are combined with irregular reeds, and the electric valve controls the weft insertion. The four-bar linkage is used for weft beating; Fully automatic continuous active double beam electronic warp feeding; Mechanical coiling, separation type external large coil device structure, using independent servo drive, automatic tension control, maximum total winding diameter can reach 1000mm; Active electronic weft storage, mechanical scissors, photoelectric weft detection device; The powerful vacuum device effectively removes small fiber dust particles generated during the operation of the loom, ensuring the physical and mental health of the operator.